Advantages of Computer Integrated Manufacturing

Manufacturing is the largest sector in the US. Remains one of the top manufacturing countries in the world.

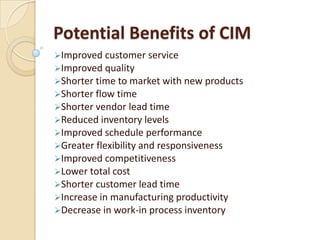

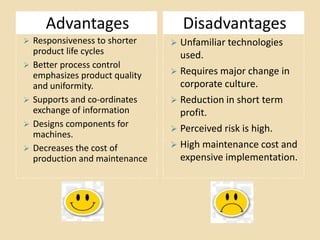

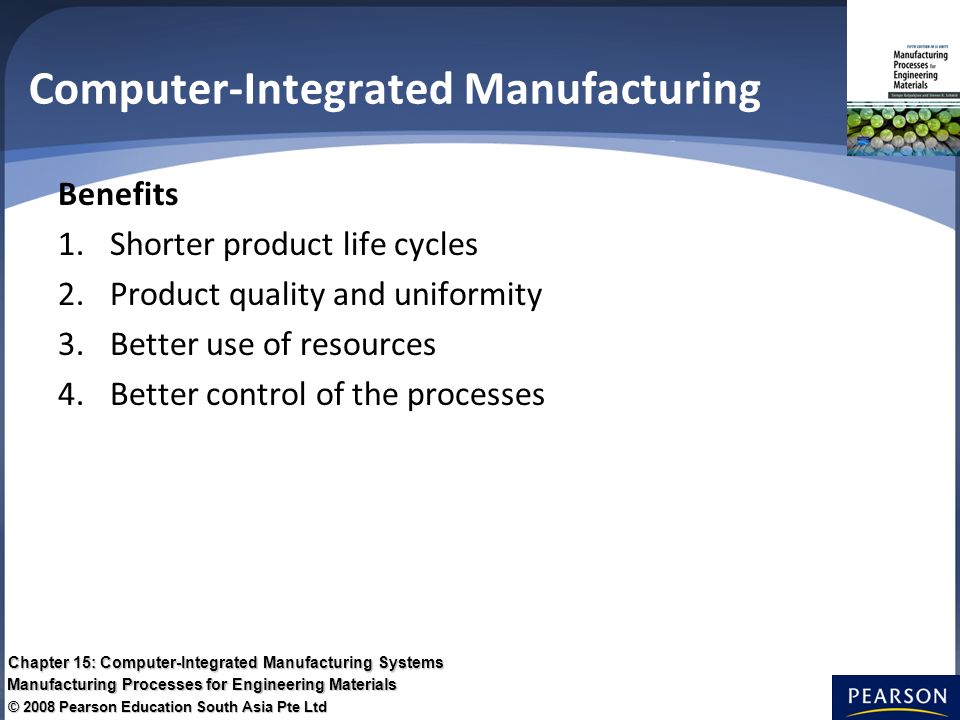

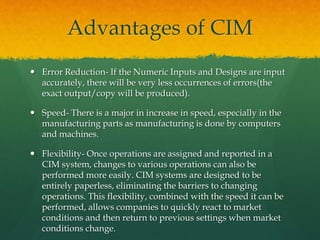

Advantages commonly attributed to automation include higher production rates and increased productivity more efficient use of materials better product quality improved safety shorter workweeks for labour and reduced factory lead times.

. Concurrent engineering CE is a work methodology emphasizing the parallelization of tasks ie. A small circuit using ICs can be obtained for a given functionality as compared with the discrete circuit. The second step involves the simulation of the circuit and modeling using CAD Computer-Aided Design.

Through these automatic updates in the initial phase the user saves his time as well as money without. Cloud-based CAD programs are becoming the norm. Although factory employment has decreased over the years the US.

In this step a thin film of insulating material like Silicon Dioxide is coated over the silicon substrate and. As a manufacturing term batch production belongs to a group of manufacturing processes that are differentiated by their scale. Despite the claims of.

For security reasons some entities are moving away from SHA-1. Higher output and increased productivity have been two of the biggest reasons in justifying the use of automation. A survey done by Business Vantage in 2016 found that up to 29 of companies using CAD plan to adopt cloud-based software in the next 3 to 5 years.

Economy adding a value of over 2 trillion each year. It refers to an approach used in product development in which functions of design engineering. By using the cloud CAD users can use the software anywhere with an internet connection and designs are.

TPM 20 products and systems have important security advantages over TPM 12 including. At 45 X 37 mm and less than 1 mm thick. Performing tasks concurrently which is sometimes called simultaneous engineering or integrated product development IPD using an integrated product team approach.

Some of the major pros are It saves time and money. The TPM 12 spec only allows for the use of RSA and the SHA-1 hashing algorithm. The third step involves photolithography.

Power Consumption is Low. The number one reason for this is mobility. The advantages of types of Integrated circuits are discussed below.

For any malicious actor to gain access such an actor must gain access to at least 51 of the network going by most blockchain networks to be able to effect a major. Manufacturing software provides your business with several tangible benefits including the following. Produces 40 percent more than it did in the 1990s.

Global Computer Aided Engineering CAE Market to Reach 87 Billion by 2026 Computer-aided engineering CAE refers to the use of computer and software solutions to design analyze and generate. Notably NIST has required many federal agencies to move to SHA-256 as of 2014 and technology leaders. Manufacturing software or an Enterprise Resource Planning system for manufacturing can be integrated with other systems for a holistic view to make adjustments based on events throughout the supply chain.

This technique reduces the effect of changes in the manufacturing process. Digital manufacturing is the application of computer systems to manufacturing services supply chains products and processes. The other two in the group are mass production products made in very large quantities usually in a continuous flow and job shop manufacturing products made in single copies or in small series often as custom.

The customer can provide early feedback on the design delivery and other requirements as they have early visibility. Integrated circuits use less power to work properly due to their less size and construction. The software has built-in modification management abilities that help in automatic updates.

Functional modules are developed in parallel as the prototypes are integrated to make the complete product for faster product delivery. Digital manufacturing technologies link systems and processes across all areas of production to create an integrated approach to manufacturing from design to production and on to the servicing of the final products. A throwaway prototype is built to understand the requirements rather than freezing the.

Thanks to mass production the US. Large numbers of tiny MOSFETs metaloxidesemiconductor field-effect transistors integrate into a small chipThis results in circuits that are orders of. Widens supply chain visibility.

CAD is used to design the photolithographic mask which consists of the glass plate coated with chromium pattern. The decentralization model or nature of blockchain technology in which each computer or node in the network owns a copy of the transactions recorded is also a basis for enhanced security. A SmartMedia card originally called a solid-state floppy disk card or SSFDC is a memory card developed by Toshiba that uses flash memory to store data and to make it portable among devices such as digital cameras personal digital assistants PDA s and other handheld devices.

An integrated circuit or monolithic integrated circuit also referred to as an IC a chip or a microchip is a set of electronic circuits on one small flat piece or chip of semiconductor material usually silicon.

Computer Integrated Manufacturing

Computer Integrated Manufacturing What Why How N Ix

Computer Integrated Manufacturing

Chapter 15 Computer Integrated Manufacturing Systems Ppt Video Online Download

0 Response to "Advantages of Computer Integrated Manufacturing"

Post a Comment